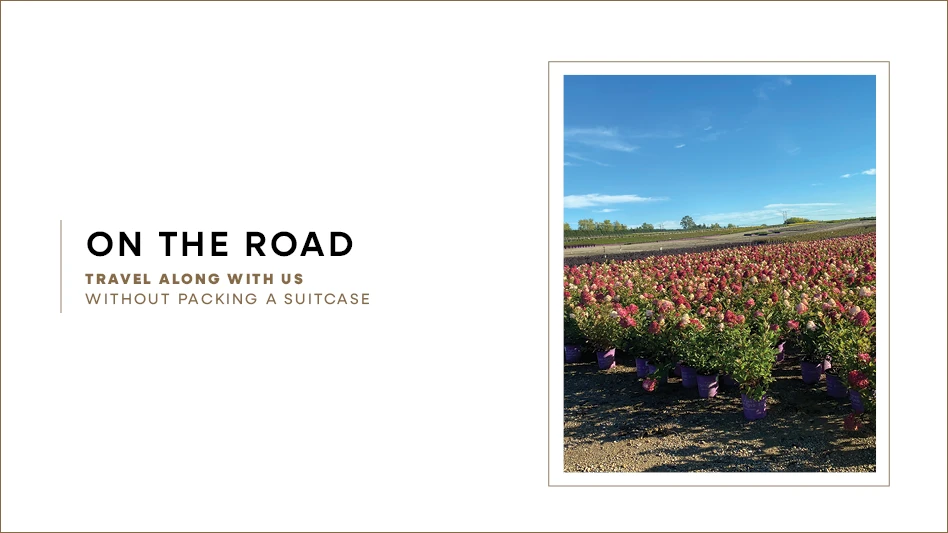

This sign greeted visitors at Siebenthaler's, the last stop on the tour.On Saturday morning, 52 Cultivate’15 attendees boarded a bus for the Nursery Production Tour. Some were groggy, some were jet-lagged, but all were ready to spend the day learning more about the industry’s supply chain.

This year, the tour covered three stops in Dayton and the surrounding area.

A. Brown & Sons Nursery

The first stop on the tour was A. Brown & Sons Nursery, a wholesale nursery which sprawls across 2,000 acres in Montgomery County and the Miami Valley area.

The nursery started as 10 acres of vegetable production, when it was founded in 1959 by Anthony (Tony) and Helen Brown, along with their six children John, Harry, Barbara, Ken, Vernon and Mike. Anthony had emigrated from Germany to the U.S. in 1929 and Helen was the daughter of German immigrants.

The nursery really took off in 1971 when Kenny and Vernon Brown returned from serving in the Vietnam War. The nursery is named after their father, Anthony, and has grown immensely in its 56 years of existence. Currently, seven of Anthony’s grandchildren work in the business. The third-generation of Browns is going strong.

When the recession hit in 2008, many area farmers went under. Ken Brown, the president of Brown’s Nursery, saw an opportunity and acquired many smaller farms during the recession, adding to its production space.

“He was buying farms when everyone else was getting rid of land,” says Kevin Ganger, biologist for A. Brown & Sons Nursery. “And every acre is bought and paid for.”

Ganger describes A. Brown & Sons irrigation system.

The Brown family has purchased much of the surrounding farmland and converted it to nursery use. The operation has swollen to 52 farms, many of which are named after the farmer who originally worked the land. Instead of numbered fields, names like Milligan Farm or Marshall Farm are common.

Ganger says the nursery decides what to plant on the newly acquired farms based on the soil type.

Ganger says the Brown family’s secret to success is quality product. The nursery doesn’t advertise, doesn’t do anything in the way of marketing. The trucks that ship Brown trees to west to Colorado, east to New York, north to Minnesota and south to Tennessee, bear no markings identifying their home nursery. That’s the way Brown’s has always done business, and the nursery has no plans to change anytime soon.

“Most of our business comes from word-of-mouth,” he says. “Someone buys a tree and tells a friend.”

A. Brown & Sons Nursery grows the tried-and-true crops that landscapers want. Ganger says the fact that the nursery sells large specimens, up to 5-inch B&B trees, means that the nursery needs to think long and hard about adding new varieties to its product line. There are some trees that won’t sell for 10 years. While he’d love to grow items like blue beech, many customers don’t want that long of a return on their investment. Hardiness is another major consideration.

“If it isn’t zoned for this area, we’re not going to grow it,” Ganger says.

Another key to the nursery’s success is its strong boxwood program. Concerns about boxwood blight haven’t touched Brown’s – the nursery grows 35,000 to 40,000 buxus cuttings each year. It’s all homegrown. While most bareroot trees grown at the nursery arrive as liners from the west coast, almost all of Brown’s shrubs are propagated in-house.

Ganger received plenty of questions on the tour about his irrigation and soil testing systems, especially the drain tile-based irrigation system.

Dayton Bag & Burlap

Have you ever wondered how the burlap and wire baskets used in B&B tree production are made? It’s a fascinating process, with huge demands and a 12,000 mile supply chain. All burlap comes from India, and Dayton Bag & Burlap has to keep three million yards in current inventory to keep the plant running. According to Bob Couch, horticultural sales manager, the company added wire basket production in 2003 to stay competitive. The company builds 60,000 to 70,000 wire baskets per week, nearly 3 million per year.

The company has six distribution centers throughout the U.S., but every one of its wire baskets are made in its Dayton manufacturing facility and headquarters.

Employees at Dayton Bag & Burlap weld wire baskets.The 105-year-old company is one of the few burlap producers in the country, and the only one that handles the treatment process itself. As an organic material, burlap is vulnerable to pests and molds. Dayton Bag & Burlap has an EPA-approved treatment process involving a copper carbonate solution to kill mold.

Tour attendees were able to see the process firsthand, as the material makes its way from large rolls through the plant to where it is treated with the EPA-authorized chemical solution to prevent pest or disease issues from affecting the organic material.

The manufacturing facility was built in 1890, and is filled with many machines the company built itself to accomplish very specific tasks, like the dryers that use 10 tons of steam per hour to dry the burlap after its cleaning soak, or the machines that use 90,000 parts to build 10,000 wire baskets.

The company’s 150 employees work day and night to produce the amount of bags and baskets required by the nursery industry. In the spring, they work to rebuild the inventory. Around Labor Day, things slow down, only to pick up again around Dec. 15, when Oregon and Texas nurseries start ordering.

The nursery industry accounts for 90 percent of the company’s sales, says Sam Lumby, president of Dayton Bag & Burlap.

“The last bastion of burlap is horticulture,” Lumby says.

The company’s burlap is also used in sandbags purchased by the U.S. government. The company has been receiving unexpected business from the wedding industry, Couch says. Apparently, burlap has become a trendy material for wedding decorations. Couch has received some large orders from wedding planners over the past year.

“You’ve got to reinvent yourself every 10 years,” Lumby says. “The world’s changing, and you’ve got to change with it.”

Dayton Bag & Burlap provided a tasty cookout lunch for the tour attendees, and as they boarded the bus to travel to the final stop, Lumby’s workers came out of the plant to enjoy a company picnic.

Siebenthaler’s Wholesale Nursery

Jeff Siebenthaler, the CEO of Siebenthaler’s Wholesale Nursery says his business is what is sometimes called a landscape nursery. He has 450 acres of production, with a variety of perennials, shrubs and deciduous and evergreen trees in sizes ranging from 1.5-inch to 10-inch. The nursery has more than 20 poly houses devoted to container plants, shrubs, trees and perennials. The nursery also offers landscape design and arborist services.

Siebenthaler’s has two retail locations, one in Beavercreek and one in Centerville. The Beavercreek location that tour attendees will visit features an interesting blend directly from a well-kept and manicured retail garden center into a wholesale production nursery. It’s a design choice that aims to differentiate Siebenthaler’s retail experience from competing garden centers that don’t grow their own.

“We don’t restrict our customers from going from the retail center to the nursery,” Siebenthaler says. “There’s no line of demarcation.”

.jpg)

Jeff Siebenthaler leads the tour of his nursery.

The nursery sells 20 percent of its own product at its retail locations. About 65 percent goes to landscapers, which is the largest customer category. The rest goes to other nurseries, golf courses, garden centers and municipalities.

Siebenthaler likes to encourage innovative thinking. Each year, a team of robotics students from nearby Wright State University bring several prototype grass-mowing robots to the nursery and test them out.

Six generations of Siebenthalers have worked the fertile land of the Miami Valley. Jeff’s son, Robert, is the current president of the company, and Jeff’s father, Bob, is the chairman of the board. In the early years, the company specialized in growing fruit trees and grape vines which sold for as little as three cents.

By 1920, ornamental trees and shrubs had largely replaced the fruit trees. The company grew throughout the depression, and as the need for professional landscaping developed, so did Siebenthaler’s landscape division. The Siebenthaler Company landscaped for NCR corporate headquarters, Wright Patterson Air Force Base's Memorial Garden, the Dayton Art Institute, and the Dayton Public Library. the Ketterings and the Wright Brothers also had homes landscaped by the company.

Latest from Nursery Management

- Jackson & Perkins expands into Canadian market

- Green & Growin’ 26 brings together North Carolina’s green industry for education, connection and growth

- Marion Ag Service announces return of Doug Grott as chief operating officer

- The Garden Conservancy hosting Open Days 2026

- Registration open for 2026 Perennial Plant Association National Symposium

- Artificial intelligence applications and challenges

- Fred C. Gloeckner Foundation Research Fund calls for 2026 research proposals

- Harrell’s expands horticulture team with addition of Chad Keel