Briggs Nursery Inc. is one of the nation’s premier propagation nurseries and a leader in tissue-culture production.

In fact, Bruce A. Briggs, now deceased, was honored as the NMPRO Nursery Grower of the Year in 1999 for his lifelong accomplishments in this field.

So when the nursery, now led by Bruce’s son Gary, decided to pull up stakes and move the company 36 miles west, you could assume the new facility would be first class. Briggs Nursery did not disappoint.

The new site near

A new 52,000-square-foot Conley’s greenhouse range has Argus computer controls that allow the company to provide new transplants precise growing needs.

Rolling bench systems allow crops to be produced virtually without human contact. They also allow the company to eliminate walkways and maximize production space in the range.

Emotional experience

“It was about halfway finished when I first walked her through,”

Being one of the first production nurseries to experiment with tissue culture, Bruce’s first attempts were small scale. With tissue culture, tiny plantlets are produced in test tubes in agar solution that provides nutrients and encourages rooting. Precise light and temperature, as well as perfect sanitation, must be provided.

Bruce built the company’s first tissue-culture lab in the family’s kitchen in the 1960s. Following labs increased in size and sophistication.

Getting the lab right

Having three separate growing chambers is an improvement over the

“Having such an established staff is one of our key factors for success,”

The new tissue-culture lab was laid out with sanitation in mind. Any stray bacteria would quickly multiply in the labs and threaten thousands of plants.

Office space, a lunchroom and restrooms were situated away from the main production areas. This decreases the chances of tracking in pathogens.

Workers in the lab wear sanitary clothing. A changing room is located next to the lab.

Construction materials for the lab were selected with disease control in mind. In the previous lab, the racks were wooden. Now metal racks are used.

“Even if you sanitize all the surfaces, it’s possible for microbes to get down in the wood,”

Even earthquakes were taken into consideration.

“Our new lab is earthquake proof. The racks are designed so that nothing will break during a big quake,”

The facilities also have a secure power system and backup emergency power.

Automated greenhouse

The Conley structure’s environmental controls allow the company to monitor and maintain proper shading, ventilation, temperatures, irrigation and humidity. This is important considering plants coming out of tissue culture are very tender and need precise conditions.

The structure is covered in rigid polycarbonate sheets instead of soft polyethylene.

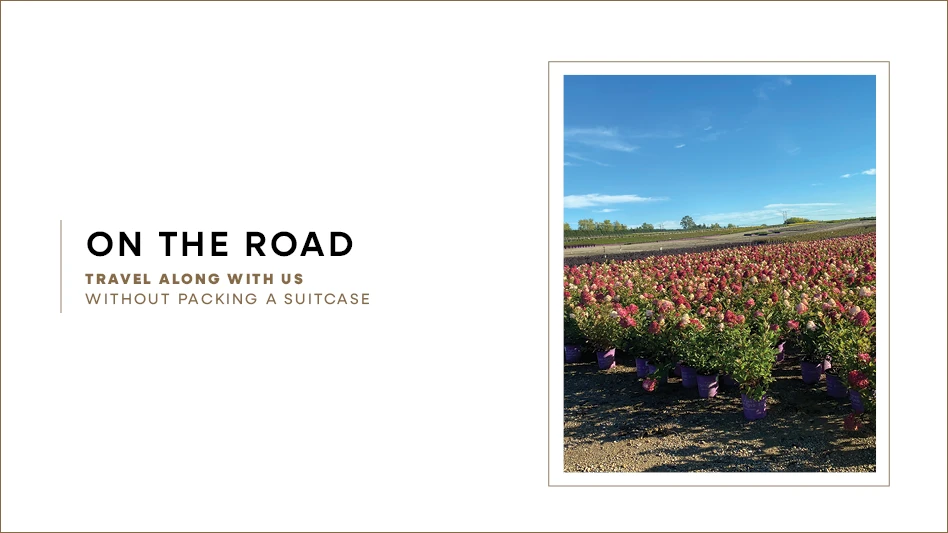

The company typically has about 1,000 varieties of plants in production in this house at any given time.

“What we’re seeing in the new structure is that the plant materials are moving through much quicker,”

Newly transplanted material from the tissue-culture labs are placed on the company’s rolling benches. As these crops age, they gradually move down the length of the greenhouse. By the time they reach the end they’re ready for shipping.

At this point they’re automatically rolled onto trailers, bench and all, and shipped to customers. So virtually no human handling is needed.

The company has about 400 rolling benches

No overnight move

While the company’s move to the new site is impressive, it didn’t happen overnight. In fact, it was a 15-year project.

Bruce and Gary picked the location and purchased it in 1991. The company wasn’t completely moved into the new site until 2006.

“The site is actually on an ancient river bed, so under about 15 inches of topsoil it’s rock. We scraped that away and it was virtually ready for production. We didn’t need to move in any gravel beds or anything like that,”

The one concern was the climate. Located farther west, the Briggs family feared weather wouldn’t be as cooperative as it was in

“We worried it would be wetter with less sunlight. But when we compared weather stations at the two facilities, the new one actually has more light and more breezes. There is more rain, but only in the winter, so that’s not a problem.”

The long duration of the move had to do with the company’s crop cycles.

“It’s tremendously difficult to schedule a move around our production. If I’d won the lottery, it would have gone much faster,” Briggs said. “But we had to maintain our production and our cash flow, so things had to be done a piece at a time.”

{sidebar id=2}

For more: Briggs Nursery Inc., (800) 444-1515; www.briggsnursery.com.

- Todd Davis

Founded: 1912 by Orson Briggs as Briggs Fruit Farm.

Location:

Acres: 400.

Crops: Primarily liners, but some finished stock.

Specialty: The company was one of the pioneers of tissue-culture woody plant production.

Employees: Fluctuates from 150-300.

Latest from Nursery Management

- Jackson & Perkins expands into Canadian market

- Green & Growin’ 26 brings together North Carolina’s green industry for education, connection and growth

- Marion Ag Service announces return of Doug Grott as chief operating officer

- The Garden Conservancy hosting Open Days 2026

- Registration open for 2026 Perennial Plant Association National Symposium

- Artificial intelligence applications and challenges

- Fred C. Gloeckner Foundation Research Fund calls for 2026 research proposals

- Harrell’s expands horticulture team with addition of Chad Keel