|

For Decker’s Nursery to stand behind a new introduction, it’s got to be more than just a pretty face. When a breeder brings a lovely new addition to the team at Decker’s, it has to be tested and proven to perform well.

“We test and trial plants in the nursery and expect at least two good, strong growing seasons before we put our name behind it,” said Mike Miller, general manager at Decker’s Nursery in Groveport, Ohio. “We have to weed through the 85 percent to find the 15 percent that are worthy to go on the market.”

Decker’s grows liners, grafts and finished plants for growers, garden centers and landscape contractors. During the last few years, Decker’s has shifted its focus to growing new introductions – plants that create excitement in the industry.

Decker’s is forging partnerships with breeders to grow liners of new selections from companies like Novalis, LCN Selections, PlantHaven and Proven Winners.

“New introductions are a nice product to work on and we see those as having the most upside in this down economy,” Miller said. “There are some very exciting plants that will be coming into the market over the next couple of years.”

New introductions are at the forefront of the nursery’s stability and growth, Miller said.

Some new items include Lemon Daddy hydrangea, Lo and Behold ‘Blue Chip’ buddleia, Snow Splash hypericum and ‘Orange Rocket’ barberry.

“We can provide liners of these great new plants to our progressive customers,” he said.

In 2004, Decker’s built a 3-acre propagation and liner production facility. The propagation facility was built with a central walkway and nine individual houses to create many microclimates. The houses are equipped with mist and heated floors.

Decker’s produces 750,000 cuttings annually and ships product nationwide.

Another one of Decker’s specialties is grafted material. The nursery grafts 100,000 upright juniper, 20,000 spruce and 5,000 pine each year.

“Grafting has been a cornerstone of our liner production for many years,” Miller said. “It’s a great product for two reasons – it’s an unusual product line for our customers and it allows us to keep our employees working during the winter.”

Nursery innovation

To help decrease costs and increase efficiency, Decker’s Nursery creates systems for each step of production.

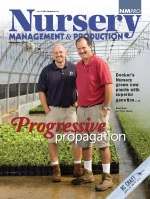

From potting containers to taking cuttings and grafting, Decker’s looks at a task and breaks it down into individual steps. “We look at each step and see how we can make it faster, easier and more efficient,” Miller said. “Then we pull all the steps back together to see if it works as intended and make adjustments where they’re needed.” Mike Miller (left) is general manager and Brian Decker is president of Decker’s Nursery in Groveport, Ohio.

Mike Miller (left) is general manager and Brian Decker is president of Decker’s Nursery in Groveport, Ohio.

Photos by Jerney StudiosThis past spring, the nursery revisited how workers stick cuttings.

“We bought some growing racks and some dimple plates and try to direct stick as much as possible. About 85 percent of our summer cuttings will go directly into the pot they’ll be sold in,” he said. “We used to stick inside the house, but that got the floor dirty, creating an extra step of washing the floor when we were done.”

Most of the tasks are labor intensive, and the majority of the nursery’s costs are tied up in labor.

“We’ve dropped our labor costs by around 25 percent each year the last two years,” he said. “Certain motions have to occur, but we ask ourselves if those motions can be made easier.”

Decker’s eliminated at least one person from the potting machine by using rolling racks that transport plants to the potter. The nursery communicates production plans to all department managers.

“We’re a very connected nursery. By having all of our managers know what is going on in other departments, we can shuffle employees to areas that need more help at certain times. Being organized and getting things done on time sounds simple, but can save an enormous amount of time,” Miller said.

Besides decreasing labor costs, Decker’s also cut back on supplies that must be warehoused. Instead of buying extra fertilizer, pots or soil, the nursery buys just shy of what’s most likely needed, knowing it can buy more.

Decker’s also “re-fabricates” machinery such as turning an old potting machine into a flat-filler. The nursery also built a liner trimming machine that allows the crew to trim its 3-acre liner container area in about two days.

The nursery also is experimenting with shipping racks to save labor and costs.

“As our focus changed to liners, shipping some orders became more cumbersome. We started using metal racks to ship outside our regional shipping area. This has been a wonderful success,” Miller said.

The metal racks are a 40-inch by 48-inch pallet with a metal frame and shelves made from OSB. The nursery fits eight flats per layer, up to eight layers.

“We’ve calculated that 27 flats is the tipping point at which the rack system is less expensive than the boxing cost,” Miller said.

Decker’s also is testing a cardboard rack system that weighs less and costs less.

“There are some limitations with the cardboard system. Shelf spacing is set to a predetermined height. And the durability on long hauls will have to be tested better next spring,” Miller said.

For more: Decker’s Nursery, www.deckersnursery.com.

Explore the November 2010 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- [SNEAK PEAK] Leading Women of Horticulture: Louise Schaefer and Susan Tantsits

- The Growth Industry podcast Episode 10: State of the Horticulture Industry

- Tennessee Green Industry Field Day scheduled for June 11

- UTIA and UT Knoxville research teams will develop automated compost monitoring system

- Ken and Deena Altman receive American Floral Endowment Ambassador Award

- [SNEAK PEEK] Leading Women of Horticulture: Becky Thomas

- [WATCH] Taking root: The green industry’s guide to successful internships

- [SNEAK PEEK] Leading Women of Horticulture: Angela Burke