© Doug Freidman, Undefeated Media

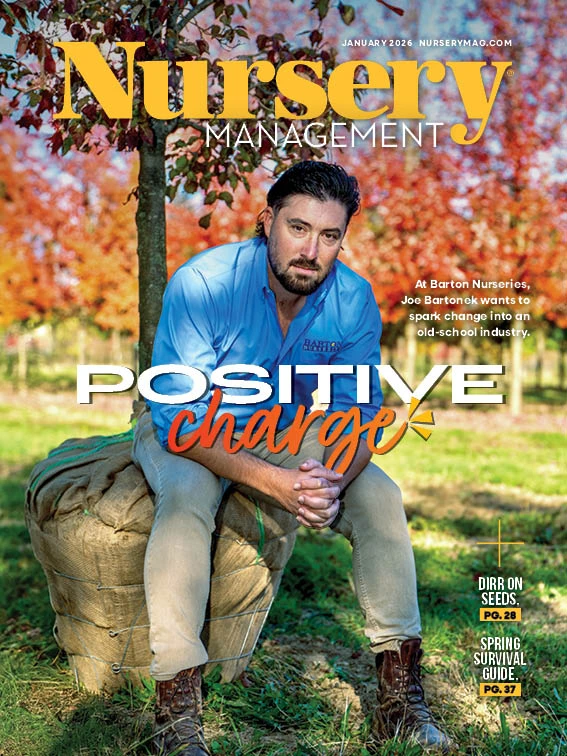

The Princeton Sentry Ginkgo biloba seen on Barton Nurseries’ logo is Joseph “Joe” Bartonek’s favorite tree. The second-generation nurseryman and president of Barton Nurseries says he sees a resemblance between the company he runs and the tree on its logo.

This particular gingko is one of the many varieties developed by the legendary Princeton Nurseries, a neighboring New Jersey institution with a legacy that still looms large. Ginkgos have been part of our world since prehistoric times. Their leaves, rich green and shifting to a dramatic bright yellow in fall, may have made a tasty snack for a brontosaurus.

Adaptable to any soil type, low maintenance, an impressive columnar habit — it shares many qualities Joe prizes — like that legendary longevity.

“It’s a tough, hardy, sturdy tree and (like the ginkgo) we plan on being around for generations to come,” Joe says.

The beginning behind the name

The business was founded by Joe’s father, Joseph Bartonek, Sr. He started out mowing lawns in the Clara Barton neighborhood of Edison, New Jersey. Barton founded the first free public school in New Jersey, worked as a nurse during the Civil War, earning the title “Angel of the Battlefield.” After the war, she founded the American Red Cross and continued working as an activist for women’s rights. She’s a local hero, and since all of Joseph’s early work was in the part of Edison named after her, he named his business Barton Landscaping.

The fact that his last name is Barton with an -ek at the end is just a coincidence.

In the 1960s, Joe’s father was building his business, working on high-end residential projects and summer homes down the Jersey Shore.

Then he purchased land in Edison and began procuring material from nurseries on the West Coast and elsewhere. He needed a holding yard for the plants he was using in his landscaping jobs. It turned into a little garden center, and landscapers began to ask him if they could buy from him directly. That’s how Barton began re-wholesaling to other landscapers. The business grew, and Bartonek bought a 12-acre farm in North Brunswick, and lined it out with trees and shrubs.

“He realized we can grow a better product than some nurseries and have more of a handle on the supply chain,” Joe says. “We started growing and it took off from there.”

In its early days as a grower, Joe’s father went to Princeton Nurseries to buy liners. In the early ‘90s, Barton continued its growth by buying a literal part of Princeton Nurseries. Barton’s 500-acre Cranbury location was a satellite farm for Princeton, the now-defunct giant. Now it’s a 500-acre field growing operation for Barton. Barton also has a 125-acre growing facility in Robbinsville, New Jersey.

Today, the company is nationwide. Barton grows more than 1,000 varieties of trees and shrubs. Production is mainly B&B trees and shrubs, with a small amount of containers.

Barton does business with landscape contractors, landscape architects, garden centers and re-wholesale yards across the U.S. It also brokers material from various suppliers throughout the U.S. and ships to various states, not just New Jersey.

“We don’t say no to anything, so we’ll go out of our way to find material and ship it to a job site or to another nursery,” Joe says.

Barton still has the rewholesale yard and garden center as part of its business, as well. The nursery nurtures relationships with universities, like the nearby Princeton University and others like Duke University. Barton caters to municipalities, New York parks and has even shipped trees to Arlington National Cemetery.

A positive spark

Joe has been full-time, boots on the ground, at Barton Nurseries for 12 years, after he graduated from Delaware Valley University with a major in agribusiness. But in some ways, he’s been full-time his whole life.

“Whenever I didn’t have school, I would be out on a digging crew, doing deliveries, inventory, being a salesman,” he says.

Basically, he’s been learning how to be a nurseryman for as long as he can remember.

“There’s pictures of me as a kid on a tractor with my old man,” he says. “And even when I was at college, it was my responsibility to come home every weekend to work on the farm.”

Joe had several roles before becoming president of the company four years ago. Joe’s brother, Michael, is active in the company as well, as a utility team member. Joe’s mother, Christine, is finance manager. His father, Joseph Bartonek Sr., was inducted into the New Jersey Nursery and Landscape Association Hall of Fame in 2015. Now 81, he stays out of the day-to-day business.

His mother is still involved, handling accounts payable and accounts receivable, though the nursery is slowly transitioning into new workflows and ERP systems, inventory management software and CRMs.

Joe pushes to adopt more modern business practices because although some nurseries don’t rely on technology, he believes it’s necessary to modernize the business.

Like many others in the industry, labor costs are one of his primary concerns. And he believes adopting technology can cut down on labor costs.

Joe wants to use technology to help forecast the nursery’s long-term production plan. In many cases, it takes three-to-five years to produce a saleable plant.

“An important part of the job is planning and so some of these tools help with the planning,” he says.

It may sound surprising, but he’s even experimenting with using artificial intelligence at the nursery. The first place he’s targeting for an AI makeover is the office.

Joe says Barton is working on using AI to help answer phone calls, take notes, and even handle some accounting tasks at the nursery, including AP and AR. It’s still in the testing stage, but the goal is to go live with the system in spring or summer of 2026. Joe understands that he’s pushing into unfamiliar territory here, at least for the nursery industry. But he believes that someone needs to take the first step.

“I’m just excited about it, because I’ve been waiting for years to do something like this and update our workflows and our systems,” he says. “But I’ve always had pushback on it from my father. He’d always say ‘no one does that in our industry,’ well, why do we have to look at everybody else? Why can’t people look at us and follow us?”

Industry events like trade shows are great opportunities to network and find potential partnerships. At MANTS 2025, Joe found a potential way to implement AI technology in the field at Barton Nurseries. He learned about Burro, the robotics company, and was intrigued by the idea of using the autonomously-driven robots with grass-cutting attachments in his field rows. He’s made plans to test drive that technology, and he’s also looking into using a drone for spraying pesticides.

There are several advantages to spraying via drone. Joe likes that team members don’t have to physically do the task themselves. It’s healthier for the individual who was doing the spraying, and it frees workers up to focus on other responsibilities, assuming you have the employees to do the work in the first place.

“Not putting it down, the nursery industry is still considered ‘old school,’” Joe says. “Nursery owners put money into steel, into equipment. They’re purchasing all this equipment that, yes, gets the job done more efficiently. But you don’t have enough staff members to run that equipment. That’s why I believe the industry should invest into technology and AI, as well.”

It’s a new way of thinking, but Joe believes growers who are open-minded will benefit in the long run.

“Instead of saying ‘it won’t work,’ ‘it’s too much money,’ ‘not in our industry,’ I believe we have to look long-term,” Joe says. “The industry isn’t looking long term, technology-wise, but we look at long-term production-wise. I believe it goes hand in hand.”

Changing the mix

The sandy loam soil on Barton’s farms is perfect for drainage. Joe says the loam content is particularly beneficial for Prunus varieties.

“I would say we grow just perfect, beautiful cherry trees because of the soil,” he says. “We do a great job with our ginkgos as well.”

Barton’s top-selling ginkgos are Autumn Gold, Golden Globe and Princeton Sentry, the tree from the logo.

In an effort to diversify and stay atop of industry trends, Barton is growing more native plants and trees.

Barton says he’s seen a huge demand increase for understory native trees. In contrast, the market for large, canopy shade trees — oaks and maples — has died down since the pandemic era.

“We definitely hope it comes back again, but it seems like everyone wants native understory trees,” he says. “They’re being planted under powerlines. Landscapers and municipalities both like that they’re low maintenance, not ripping up sidewalks.”

Joe says columnar trees are also selling well. Some of the most popular are Armstrong red maples, Bowhall red maples, Green Pillar pin oak, Kindred Spirit and Regal Prince columnar oaks and Zelkova serrata Musashino.

Joe purchases some native liners from Pinelands Nursery, and grows them to offer a specimen-size finished product from local seed source.

Tom Knezick from Pinelands Nursery is currently the president of NJNLA, and Ryan Overdevest from Overdevest Nurseries and Joe are members of the board of directors. Joe enjoys working with his fellow young nurserymen, who share his goal: to positively change the industry through improved sustainability and the introduction of new plants.

For instance, Barton took the immensely popular (and invasive) Bradford pear tree out of production four years ago. The last ones are in the field now, with no more coming. Joe isn’t worried, however.

“There’s more to the nursery industry than just a pear tree,” he says. “There’s so many other beautiful varieties.”

He considers it part of his job to educate his customers and the industry about this issue and alternative options that could fill the same niche. When landscapers come to Joe asking for Callery pears, he points them toward Winter King hawthorn or Donald Wyman crabapple, or maybe ‘Ivory Silk’ lilac.

“Being in the green industry and trying to beautify the environment, it’s our responsibility to replenish the landscape in a positive way,” he says.

Leadership lessons

Loyalty is important to Joe. It’s one of the core values he learned from his father, and it’s paid dividends in business.

Fellow second-gen nurseryman Carl Hesselein at nearby Pleasant Run Nursery said one of the reasons his father got off to a good start when he started his nursery was due to orders from Barton. It’s a similar story with Robinson Nursery all the way across the country in Oregon. Today, Joe buys bareroot liners from Josh and Chris Robinson, but when their parents started the nursery in the 1980s, Joseph Sr. tried to buy as much as he could from them to help them gain a foothold.

“Even though we’re all competitors in this industry, there’s still enough to go around,” Joe says. “And instead of being enemies with one another, how can we figure out how to work together instead?

Joe says his father was also always loyal to suppliers. Because without a supplier, you wouldn’t have anything to offer to your customers.

When he receives a frenzied call from a customer, Joe answers calmly. He tells the customer yes, we’ll make sure we’re there when you arrive, yes, the plants you are ordering will be there, yes, you can pick them up.

“We hate to say no to people,” he says. “And we always want to meet their deadline because we’re all on the same team.”

If an order isn’t ready for an unexpected pickup, the Barton team will drop its current task to take care of it.

One of Joe’s goals as a leader is to put the proper tools in place for his team to succeed. He’s incorporated what he learned under Joseph Sr., but prefers a more hands-off management style.

Barton Nurseries is celebrating 60 years in 2026. Despite all of its successful partnerships, in some ways the company is fiercely independent. Joe’s fond of saying that just because something works at another nursery, it doesn’t necessarily mean it’s going to work at theirs.

New employees undergo an onboarding process known as “Bartonization.”

“We have to Bartonize you,” Joe says. “Forget about what you learned anywhere else, wherever you were before, let’s teach you our way. Then once you respect our way, we’re able to respect you to show us a better way of doing it.”

Explore the January 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- Jackson & Perkins expands into Canadian market

- Green & Growin’ 26 brings together North Carolina’s green industry for education, connection and growth

- Marion Ag Service announces return of Doug Grott as chief operating officer

- The Garden Conservancy hosting Open Days 2026

- Registration open for 2026 Perennial Plant Association National Symposium

- Artificial intelligence applications and challenges

- Fred C. Gloeckner Foundation Research Fund calls for 2026 research proposals

- Harrell’s expands horticulture team with addition of Chad Keel