Here are a few highlights:

In opening his State of the Industry address at Cutlvate’23, Dr. Charlie Hall poked fun at himself.

At Cultivate’22, Hall said there was a chance of recession in the next year. That, to date, has not happened. So, as Hall put it, his predication was technically correct.

“Last year, I stood in this exact same spot,” he said. “I predicted a 50% probability of a recession occurring, which by definition means there was a 50% probability of a recession not occurring. And I’m pleased to report that I was 100% correct.”

Here are three takeaways from Hall’s presentation.

Most growers reported increased profits in the first part of 2023

According to Hall, sales were generally strong in the first half of 2023. Seventy-six percent reported increased gross sales year over year. Sixty-nine percent of growers reported net profits this year vs. last.

The 31% of growers who didn’t report increased profits, Hall said, could have been facing increased input costs that cut into profit and/or growers not raising prices enough (or at all) to stay in line with rising costs.

He also noted that labor costs continue to rise. Non-agricultural wages are up 18% since 2018 nationally. By comparison, agricultural wages have risen 25% over the same period.

25-35 year-olds are a potential boom market

According to Hall, there is a “historical amount of 25-35 year-olds in the country now.” That, he said, is a potential market to drive new plant sales, provided they begin purchasing homes.

The next step, then, is for the supply of homes to meet possible demand on top of interest rates settling in at a level that makes mortgages more affordable. (Interest rates going down, Hall said, will be a “shot in the arm for home sales.”) On the supply side, the number of permits for new builds is increasing nationally — an indicator that the housing marketing could head in a direct that is good for the green industry.

A recession isn’t imminent

Toward the end of his presentation, Hall answered the question he joked about at the beginning: Is a recession coming or not?

Various economic indicators, Hall said, indicate that there’s over a 50% chance of some kind of economic downturn. In his own projections, he’s come to the same conclusion. However, he said, that doesn’t mean a full-on recession is coming.

Instead, Hall said, there’s “a high probability of a mild, short-lived downturn” during the first quarter of 2024. From there, he said, business should kick back up once the busy spring season drives sales.

Growers discuss the challenges and benefits of automation

No matter the scale of your nursery operation, automation can be a worthwhile investment for many reasons. But what type of automation would be best for your company? That was the big question a Cultivate’23 panel aimed to answer.

The panel was moderated by Rob Lando, chairman of AmericanHort’s board of directors. Lando co-founded AgriNomix, the Ohio-based automation supplier that is now part of AdeptAg, a family of companies founded in 2022.

Being a low-cost producer is tremendously important if you want to be a profitable growing operation, Lando said. Labor costs have increased 25% compared to 2019.

“Automation isn’t the answer to the labor problem but it is part of the solution,” Lando said.

Three growers shared their experiences with automation on the panel: Brian Groves, project manager at Panoramic Farms; Mike Miller, general manager and CEO of Decker’s Nursery and Bud Summers, COO of Everde Growers.

Summers talked about the importance of knowing your nursery’s labor costs. You can’t have an accurate idea of when your automation’s payback will occur if you don’t know how much you were spending to do the same job without automation.

Miller agreed, and said growers need to define the process they’re considering automating, account for all support and be brutally honest.

“If you can’t measure it, you can’t manage it,” he said.

At Panoramic Farms, Groves said uncertainty about how to determine return on investment contributed to a hesitant approach to automation.

“We didn’t know what we didn’t know, and that’s why we waited so long to automate,” he said.

Miller suggested looking for “low-hanging fruit” – projects that can show the benefits of automation without reconfiguring your entire nursery.

Visiting other nurseries that have automated parts of their operation can help you identify these sort of projects and determine where your biggest labor costs may be. Look for something with a comparatively low cost and low difficulty to set up and running.

Groves agreed, and said automation to his loading dock was the best low-hanging fruit with the easiest entry and quickest payback. He also said a $15,000 EZ Cut trimmer was a good introduction to automation for his crew. It provides a better more uniform cut when trimming plants and a vacuum clipping collection system. That makes the job easier for employees who are sometimes reluctant to embrace automation and “shows them that machines aren’t the enemy.”

Another topic discussed was preventative maintenance. The machines that make automation possible do need to be maintained regularly.

“It’s only making money when it’s running,” Summers said.

One question from the audience addressed short-term tasks. If you only do a certain job for one or two weeks out of the year, is it worth automating it? How can you calculate the payback? The growers said that just because a piece of machinery is expensive that doesn’t mean it needs to be running all year round. It’s tough for growers to make their peace with that, but automation allows high intensity, fast work when it’s necessary.

Groves said he has a potting machine that sits idle most of the year, and he’s OK with that. By having it, he ensures his team can hit that task hard when they need to do it.

The growers also discussed the drawbacks of automation and how to address them with your team. No. 1 is resistance to change. Also, some difficulty getting set up should be expected.

“It’s never going to work right the first time,” Miller said.

The way your nursery is built will contribute to how you can mechanize, Summers said. Many automation solutions are wheeled machines, which require flat, hard surface to work the way they should.

Ken Fisher stresses the importance of relationships

During his opening speech at the State of the Industry presentation at Cultivate, AmericanHort president and CEO Ken Fisher stressed the importance of maintaining relationships in the green industry. Specifically, he said, it’s important for the industry members to maintain in-person relationships that span years, if not decades.

The speech, given on Monday, July 17, featured Fisher noting that there are industry members who have attended Cultivate (or a previous version of the event before the formation of AmericanHort) for 40-plus years. Those relationships, Fisher said, are a big part of what makes the green industries special.

“It’s easier and easier, unfortunately, to let go of personal relationships,” Fisher said, noting that his concern stems from a generational shift and the ease of communicating digitally.

“It takes a long time to grow an old friend,” Fisher said. “Our industry won’t be as strong tomorrow as it is today, I have concerns, if we don’t continue to invest in our friends in this industry.” He noted that it will be a priority for AmericanHort to provide the in-person events that can help foster long-lasting bonds.

Fisher also made his case for growers to advocate on behalf of the industry. Fisher, along with AmericanHort senior vice president Craig Regelbrugge, spent time discussing ongoing labor concerns and the need for H-2A and H-2B reform. Fisher advocated for industry members to work with their congressional representatives and push past politics to make the case for what the industry needs. That could be by directly contacting elected officials and/or working with AmericanHort in their efforts to lobby elected officials on various topics.

“We can’t hope that regulatory issues will skip us or get taken care of by someone else,” he said. “... We have to demonstrate, as an industry, our strengths to protect our weaknesses.”

How to cultivate cultivars

Nancy Buley is Director of Communications for J. Frank Schmidt & Son Co., wholesale tree growers of Boring, Oregon. During her Cultivate education session, Cultivating Cultivars: Urban Tree Cultivar Development, she explains the lengthy process of tree cultivar development.

A formula for tree cultivar development is time + skill + patience = trees. It takes a lot of all three elements to produce quality trees, especially time.

“To grow tree trees it requires a great deal of optimism and faith in the future,” Buley said. “We’re looking at crops that are five to seven years out, and the crystal ball isn’t as clear as people might think. There’s a lot of guesswork, and it’s a really challenging business.”

Field/Liner Production Timeline

Growing trees is a team effort, and trees go through many phases on their journey to the landscapes. The propagation process usually runs for five to seven years. Then the trees are sold as bare root or in small containers to a grower. The entire production timeline ranges from six to 17 years or more.

- Years 1-3: Planning, seed, cuttings, grafting, tissue culture

- Years 2-3: Transplant seedling to field, bud scion wood to rootstock

- Years 3-7: Grow and train grafted transplant

“Propagators plus growers plus time, and you’ll have landscape-ready trees,” Buley said. “We’re always looking five to seven years in the future, and one of the challenges is sourcing seed and cutting materials and grafting materials. That takes a lot of planning to match up the number of buds you need for the number of seedlings you’ve grown, and just getting all that ready so you can start pepping the fields and estimating labor.”

J. Frank Schmidt & Son Co. propagate from seed and cuttings, and they contract with several micro-propagation nurseries. The cuttings root quickly in the humidified area in their hoophouses. The cuttings will be in the hoophouses for a season. Then they’ll be dug and transplanted in raised beds for another year. Then they go into the field, and a season later they’re one-year trees.

“So that one-year tree is actually a three-year-old tree,” Buley said.

Next, they stem the trees and bring up one bud. Then every week stakes are put down to make sure the trees are nice and straight. The trees will be pruned, graded and off to the customers.

New cultivar development

“If you think tree production takes a long time, new cultivar development takes generations – a minimum of 15 years to 50 years or more,” Buley said.

J. Frank Schmidt & Son Co.’s new tree development goals are: the tree has to be better than what’s already in the marketplace. It has to have unique traits that no other tree in that species has, whether it’s foliage, flower forms, resistance and more recently, adaptability to climate.

“We’ve been looking at this warming climate and testing for and selecting for adaptability, for resilient to drought and heat in urban settings because our wheelhouse is urban trees,” Buley said. “We’re wanting trees that are adaptable to urban settings.”

Buley explains whether specifically crossed or open pollinated, a typical selection might look like this:

- Year 1: 5,000 seedlings

- Years 2-3: Keep 500

- Years 4-5: Keep 50 -100

- Year 5: 10-15 receive a code number

- Year 6: Begin growing trials with trees that have received a code number

- Years 10-15: Consider introduction of 1 tree (maybe) from the 10 to 15 that received code numbers

Advantages of cultivars for landscape trees: predictable, superior performance in landscape settings, vigor, diversity in species and improved pest and disease resistance.

“In landscape settings, you really need to know what the tree is going to look like,” Buley said. “As opposed to whether it might be wide or narrow. Landscape designers really want to know what that project is going to look like and how those trees are going to fit, so it assures their design integrity.”

Key takeaways for new cultivar development:

- Not just new, better

- Unique traits

- Resilient in urban environments

- Natural disease & pest resistance

- Easy care & well behaved

- Can it be grown profitably?

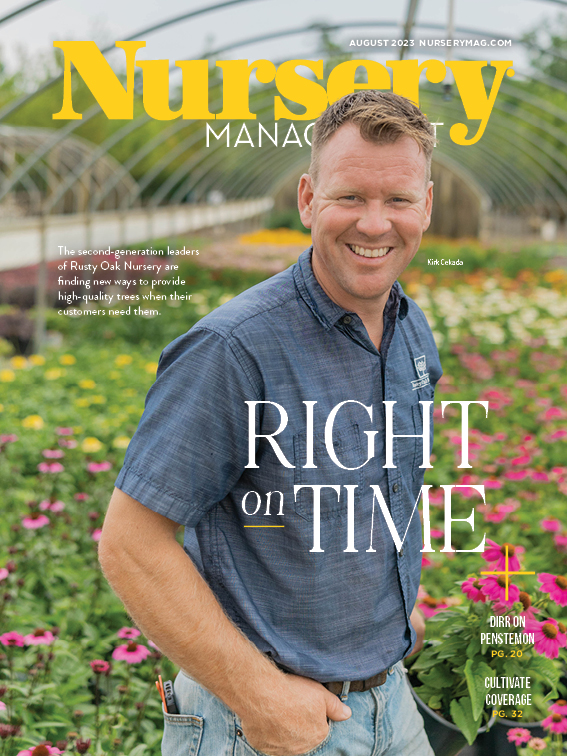

Explore the August 2023 Issue

Check out more from this issue and find you next story to read.

Latest from Nursery Management

- GardenComm 2024 Annual Conference registration is open

- Landmark Plastic celebrates 40 years

- CropLife applauds introduction of Miscellaneous Tariff Bill

- Greenhouse 101 starts June 3

- Proven Winners introduces more than 100 new varieties for 2025

- CIOPORA appoints Micaela Filippo as vice secretary-general

- Rock Star Roses

- The container challenge